Marble, the luxurious stone that has decorated the world’s greatest architectural wonders, is now at the forefront of sustainable transformation. From your favorite kitchen countertop to Michelangelo’s “David,” marble has long stood as a symbol of sophistication and artistry. However, its production and importation can sometimes lack eco-friendly measures. That’s why this article will delve deep into the concept of Sustainable Practices in Marble Slab Production and Importation. As an insider in the marble industry, I’ve seen firsthand the potential for change and have gathered a wealth of knowledge to share. So, if you’re in the industry, or simply a concerned consumer, strap in for an enlightening journey.

This article may interest you Marble or Granite for kitchen countertops

The Marble Industry’s Environmental Impact

A Glimpse into Carbon Footprint

The process of extracting, producing, and transporting marble can have a staggering impact on the environment. It often involves deforestation, enormous energy consumption, and the release of particulate matter into the atmosphere. Moreover, shipping these hefty marble slabs across international waters doesn’t do any favors to our planet’s health. Understanding the extent of this impact is the first step toward adopting more sustainable practices.

The Advent of Sustainable Marble

How it All Started

Traditionally, the marble industry has not been synonymous with sustainability. However, mounting public awareness and stricter environmental regulations have propelled a change. Companies and artisans have started adopting greener ways of sourcing and producing marble. The incorporation of recycled material, the use of renewable energy sources, and the employment of cleaner technologies have ushered in the era of sustainable marble.

How to Assess Sustainable Practices

Key Criteria

Determining whether a practice is sustainable can sometimes feel like navigating a maze. However, experts often consider three core aspects: economic viability, social responsibility, and environmental impact. These form the foundation for any sustainable operation in the marble sector, guiding businesses and consumers alike.

Regulations and Guidelines

International and Local Policies

Adhering to local and international guidelines is crucial for sustainability. Countries like Italy, renowned for their marble, have stringent laws that regulate quarrying activities and emissions. On the global scale, organizations like the United Nations offer guidelines on responsible sourcing and waste management. Keeping abreast of these regulations not only ensures compliance but also enhances a company’s reputation.

Sourcing the Right Material

Eco-Friendly Marble Types

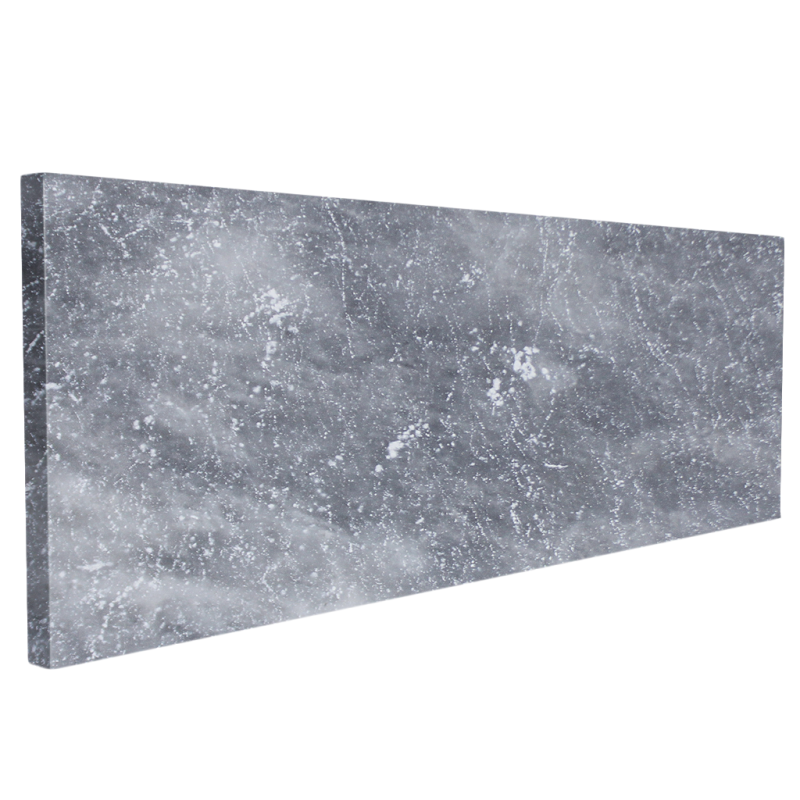

Choosing the right type of marble can significantly cut down the environmental footprint. Options like reclaimed marble or those certified by eco-labels can make a monumental difference. Such types of marble are not only visually appealing but also hold the promise of a greener tomorrow.

Reducing Energy Consumption

Innovations and Best Practices

The production of marble slabs is energy-intensive. Thankfully, cutting-edge technology is revolutionizing the way we look at energy use in this industry. Innovations like solar-powered machinery and energy-efficient transportation options are starting to take center stage. Adopting these methods not only helps in reducing costs but also substantially decreases the carbon footprint.

Waste Management

Circular Economy Models

Waste is an inevitable by-product of marble production. However, many companies are turning to circular economy models to minimize this. By recycling and reusing waste material, businesses can significantly reduce their environmental impact. These practices also create additional revenue streams, making it a win-win situation.

Sustainable Transportation

Low-Impact Importation Strategies

Reducing the environmental footprint doesn’t stop at production; it extends to the importation phase as well. Employing eco-friendly shipping methods and choosing carriers that prioritize sustainability can go a long way. As logistics become greener, so does the marble slab importation process.

The Role of Digitalization

Technology Aiding Sustainability

The integration of technology has played a massive role in promoting sustainability. Digital tools help in optimizing production schedules, tracking emissions, and even monitoring the transportation process. As a result, companies can make data-driven decisions that further their sustainable mission.

Consumer Involvement

The Importance of Public Awareness

Consumers wield immense power in shaping industry practices. Increased awareness about the ecological implications of marble production can inspire businesses to adopt greener practices. Through informed choices, we can all contribute to a more sustainable marble industry.

Future Trends

What’s on the Horizon

Looking ahead, the industry seems set for some groundbreaking changes. With the onset of 3D printing technology and advanced waste recycling methods, the future of sustainable marble is optimistic. Companies that embrace these changes stand to gain not just economically but ethically as well.

Real-world Examples

Companies Leading the Way

Businesses like StoneCycling in the Netherlands are pushing the boundaries of what’s possible in sustainable marble production. Through innovative methods like ‘WasteBasedBricks,’ these pioneers are setting new standards for the industry.

Frequently Asked Questions

What are eco-labels in marble?

Eco-labels in marble serve as certifications that indicate the product has met specific environmental and sustainability criteria. Think of them as a seal of approval, assuring consumers and suppliers that the marble they are dealing with has a reduced carbon footprint, was sourced responsibly, or meets other sustainability standards. These labels can be invaluable for discerning consumers looking to make eco-conscious choices, as they offer a quick and reliable way to determine the sustainability of different marble products.

How do solar-powered machinery work in marble production?

Solar-powered machinery in marble production works by harnessing energy from the sun, converting it into electricity, and then utilizing it to run various machines involved in the marble quarrying, cutting, and polishing processes. Photovoltaic panels are usually installed in or near the production site. These panels capture sunlight and convert it into electricity, which is either used immediately or stored in batteries for later use. The idea is to reduce the reliance on fossil fuels, thus lowering greenhouse gas emissions. The adoption of solar-powered machinery is an example of how sustainable practices can be integrated into traditional industries.

Is recycled marble as durable as newly quarried marble?

Recycled marble often involves the re-use of marble slabs and remnants, or the incorporation of marble dust into new products. While the durability can vary depending on how the recycled marble is produced, it generally tends to be slightly less durable than newly quarried marble due to the stresses it may have undergone during its previous life. However, advances in recycling technology are narrowing this gap. It’s also worth mentioning that recycled marble is often more than adequate for many applications, such as tiles and countertops, where extreme durability may not be a crucial factor.

Conclusion

The quest for Sustainable Practices in Marble Slab Production and Importation is not just an industry concern but a global imperative. The time for change is now, and the roadmap laid out in this article should serve as an indispensable guide for all stakeholders.

Pingback: Silestone Quartz: Unleashing the Aesthetic and Functional Benefits in Your Home | Fairfax Marble